Can Smart Machines Help Humans?

There has been a major upheaval in the manufacturing industry in recent years because customer expectations have been growing rapidly, owing to the rise of startups.

Reshoring Is Causing Production To Shift Home

Companies are facing the increased pressure of reshoring (i.e., bringing the production back home). Thanks to the pandemic, it became tough to hire workers in other countries. Demand also considerably reduced, due to which it was no longer feasible to operate production facilities everywhere. In 2022 reshoring will be the norm rather than just a response to the pandemic. Also, due to the pandemic cutting down production in different locations, companies can no longer choose offshoring and hence want to produce close to home. Companies have to keep pace with these changes. The manufacturing sector is largely driven by demand, due to which sometimes urgent hiring needs to be done to keep pace with changes. The companies have to adopt machines installed with sensors because competitors use the same. Hence, simulations will be needed to teach employees how to use such machines. A major use of such smart machines is happening in inventory management because companies have been facing a precarious situation due to the pandemic.

Smart Mining

Mining is also an industry where smart machines play an important role because the need for human entrance into mines is thus eliminated. Smart mining is a concept where no humans enter the mining area, and robots and autonomous vehicles are left to do the job. These machines reduce fatalities to none, and carbon emissions are nil.

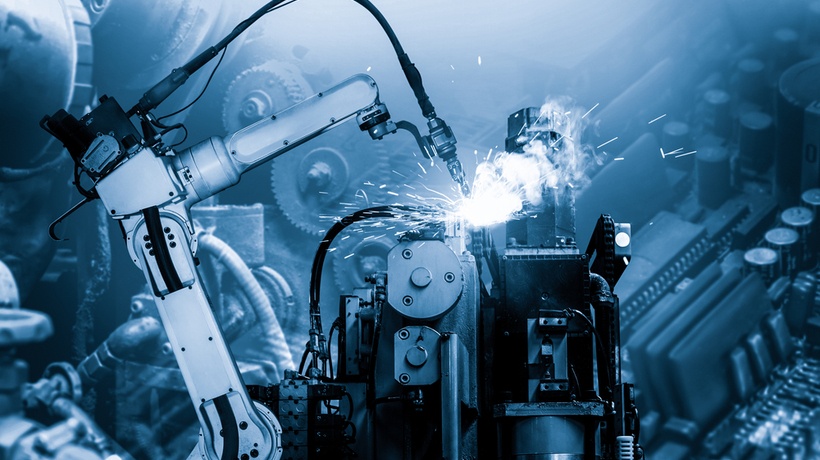

Smart machines are popularly used in companies now. They include devices such as cars and robots, which don’t require any assistance from humans to finish anything delegated to them. These machines impart a big competitive advantage to businesses because they allow for a cut in operating costs. Smart machines are also used because of high levels of access to systems such as the internet due to which large data transfer is possible between different manufacturing facilities. Also, the data storage capabilities of businesses have multiplied over the years.

Unlike ordinary machines, smart machines have better cognitive capabilities and can be programmed with Artificial Intelligence-based algorithms to make decisions. These machines are endowed with special capabilities such as voice recognition, natural language processing, etc. They can analyze human instructions.

Scheduling Of Preventive Maintenance

Smart machines can help humans by minimizing the downtime caused due to equipment failure. When companies get the privilege of predictive maintenance on machines, they can eliminate downtime and prevent material wastage caused by it. They can schedule their maintenance so that no harm is caused due to machine breakdown. Since these machines have sensors, they can collect and share data with a control system leading to faster decision-making. This also reduces the need for human intervention and helps take timely action in circumstances where a delay can cause losses. Hence, any production stoppage issues are handled in time.

Lack Of Accidents

Smart machines are built with security considerations in mind, and they can prevent operators’ accidents. Such machines minimize the risk of accidents because they ensure complete adherence to safety norms.

Since these smart cameras are empowered with AI-enabled video analytics, they help businesses ensure maximum employee safety, such as ensuring that workers wear PPE kits while handling dangerous chemicals. Cameras help detect smoke emanating from a machine in good time so that no fire-related accidents occur. These cameras are even faster than traditional fire detectors in discovering a potential fire because they use thermal imaging technology.

With the pandemic playing havoc on the availability of labor, companies have to use these machines. The companies can use remote monitoring, without needing anyone to be present on-site, through such machines. The operator can check the entire site’s operations through these machines, allowing for the safe work routines mandated by the pandemic.

With such machines increasingly used by companies, new hires have to be trained quickly in using them so that they don’t face any issues. Hence, using an LMS is mandatory for companies to train these employees. Besides learning how to use the machines, the recruits also need to learn about the vision and policies of the company. Companies can’t afford delays in the onboarding training of new employees because that means a delay in fulfilling customers’ demands.

How Can Employees Be Trained To Use These Machines?

Employees should be given proper training to operate these machines. Training in Artificial Intelligence can address skill shortages in this sector. Companies have to understand that employees have to be trained in using smart machines. A large majority of companies agree that there is an absence of skills in employees for handling these machines. The companies can’t impart such training because employees don’t have the time for it and the former also lack a budget for it. However, they can’t avoid or delay the training any longer if they want to stay in the race. Companies also have to understand that reskilling employees to use the machines has to be done on a large scale throughout the enterprise, rather than only for a small section of the workforce.

Employees must be taught data literacy when working with these machines. Since these machines generate a lot of data, employees must analyze the data as required. This involves handling the data as per the company policies. Employees also need to be able to convert the data into a usable form without any errors. Raw data is generated by the machines and hence employees have to ensure that the converted form is free from any errors. This is because if erroneous data is uploaded to the control center, it leads to wrong conclusions.

Although humans can work with autonomous machines like driverless cars, there can be accidents, and they have to be trained to avoid them. Employees have to be trained on how to use specific machines, such as when to maintain a distance during certain tasks, and animations can help them learn this better. Simulations by the machine manufacturers can be given to employees so that they can have a clear idea about how to react in certain situations with the machine.

The companies could use screencasts for simulations, but they are no longer handy when the software changes. Hence, employees should be given practice sessions on the real software of the machine. During these sessions, the hardware must not be attached to the machine so that no accidents occur due to the operator’s errors. Thus, companies can impart training to ensure employees learn how to work with smart machines.

Originally published at creativtechnologies.com.