Manufacturers are increasingly interested in the notion of a smart factory as a way to drive operational excellence. The implementation of a smart factory is a complex undertaking that demands a deep understanding of change management. In this blog post, we will explore new perspectives on how to successfully transition to a smart factory and drive greater value in the process.

A Smart Factory for Driving Value

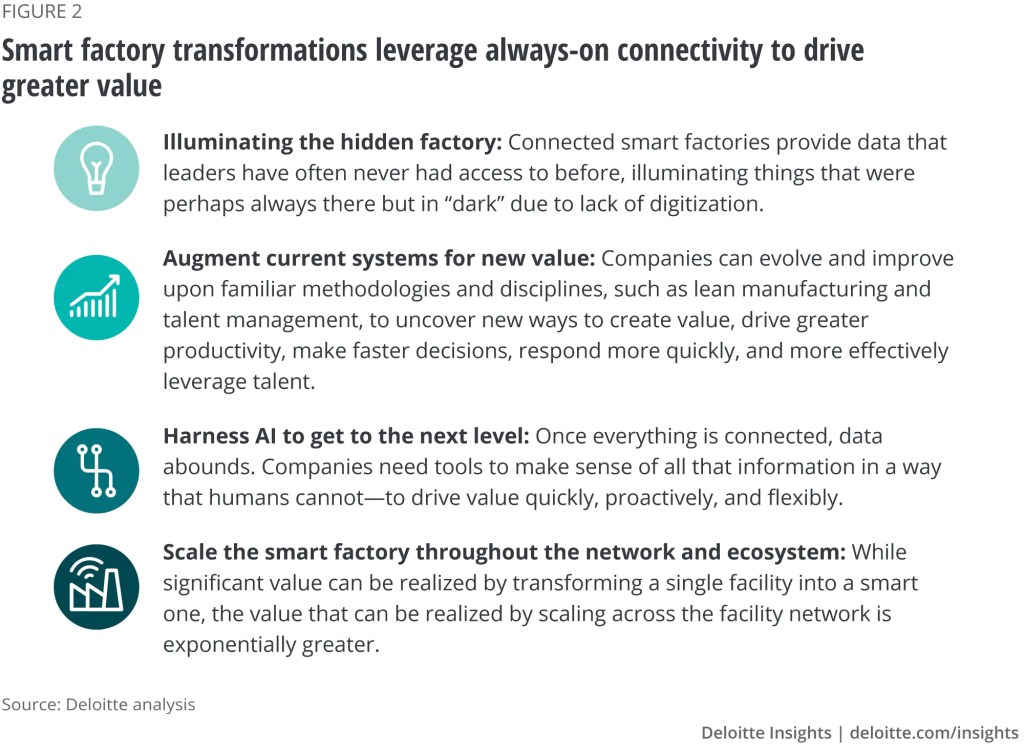

The smart factory is a digitally connected environment where automated equipment and machinery enhance process efficiency through self-optimization. The implementation of a smart factory paves the way for significant advantages; it promotes productivity, augments quality, and provides flexibility in the production process, thereby leading to a more efficient and cost-effective operation.

However, the creation of a smart factory doesn’t solely rest upon the introduction of new technologies but also on their effective utilization for value generation. This value can manifest in various ways — from efficient processes and superior product quality to heightened worker safety and robust data for strategic decision-making. Therefore, the key lies in leveraging these technologies to unlock their potential and drive significant value throughout the operation.

With a smart factory, manufacturers can streamline operations, reduce waste, improve productivity, and ultimately enhance profitability. They can also gain better insights into their processes, identify potential issues before they become problems, and make more informed decisions. In a smart factory, every piece of equipment, every process, every worker is connected and optimized for maximum efficiency and value. The smart factory is truly the future of manufacturing, offering unprecedented opportunities for value creation.

Change Management: A Fundamental Prerequisite

In any smart factory transformation, change management plays an instrumental role. It goes beyond the mere adoption of advanced technologies; it signifies a transformation in the workflow and operational processes. To ensure a successful transition to a smart factory, managing change adeptly is a crucial requirement.

Effective change management entails clear articulation of the proposed changes and engagement of all stakeholders, particularly the employees, in the transformation process. Adequate training needs to be provided to ensure smooth adoption of the new technologies. In addition, fostering a culture that embraces continuous learning and improvement is a cornerstone of change management.

“How do you make sure that you can change your processes and people when they have been working for so many years, and give them tool[s] engage them?”

A focus on sustainable changes is essential. Short-term changes may bring quick results, but for the smart factory to truly deliver value over the long haul, the implemented changes need to be durable. This means not only embedding the new technologies and processes but also ensuring that they are part of a continually improving system.

In essence, change management in the context of a smart factory is not just about the technological transition but also about ushering in a cultural shift in the organization. This shift involves a move towards embracing digital transformation, fostering an innovative mindset, and developing a workforce that’s empowered to work with new technologies. Remember, the transformation to a smart factory is not a one-time event, but a journey. And in this journey, effective change management will serve as the compass, guiding the organization towards its goal of operational excellence and value creation in a digitized manufacturing environment.

Transformation to a smart factory is not a one-time event, but a journey

Learning from the Early Adopters of Smart Factories

Those who have already taken the leap into smart factory transformation serve as a rich source of insight. These pioneers have demonstrated that the path to a successful shift is marked by meticulous planning, robust leadership, and an engaged, technologically adept workforce. Their experiences underline the significance of possessing a clear vision, establishing tangible objectives, forming a compelling business rationale, and securing comprehensive organizational alignment. They reveal that the smart factory transformation is a nuanced process, not a simple flip of a switch.

Detailed examinations of these early transformations shed light on effective strategies and potential pitfalls, providing guidance for those preparing for their own smart factory journey. This real-world wisdom can help to shape more effective approaches, circumvent obstacles, and expedite the shift towards becoming a smart factory. Moreover, these early adopters demonstrate the importance of fostering an environment that champions innovation. Embracing a culture of openness to new ideas and technologies, while continuously building on the skills of employees, proved instrumental in their success.

Therefore, manufacturers embarking on their own smart factory transformation can take cues from these trailblazers. It’s not just about embracing new technologies, but it’s about building an ecosystem where these technologies can thrive and deliver maximum value. Each transformation will undoubtedly be unique, but lessons from the early adopters can provide a valuable roadmap for navigating the journey.

In the world of content management, the acronyms LCMS (Learning Content Management System) and CCMS (Component Content Management System) are frequently used, yet often misunderstood. Are you puzzled by what sets them apart? Unsure whether your organization needs one, the other, or perhaps both? Watch our on-demand webinar, A Guide to LCMS & CCMS to answer those questions.

Realizing the Full Potential of a Smart Factory

To harness the full potential of a smart factory, there must be a steadfast commitment to iterative enhancements. Top-performing smart factories are not static; instead, they are always in a state of flux, constantly evolving, adapting, and breaking new ground in innovation. These smart factories capitalize on data and sophisticated analytics to unearth areas ripe for refinement, pinpoint chokepoints, and guide strategic decision-making. With an agile and proactive approach, manufacturers can unlock the full capabilities of their smart factories.

The drive to improve shouldn’t be sporadic, it needs to be woven into the fabric of the smart factory’s operations. Each data point captured, every process assessed, and each decision made should be done with the intention of learning and improving. The goal is to stimulate a cycle of ongoing advancement that feeds on its own momentum.

Creating such an environment doesn’t happen overnight, but it’s the next leap toward achieving operational excellence. Each stride taken on this journey not only brings the company closer to its vision but also ensures that the smart factory’s potential is fully harnessed. It’s about continually pushing boundaries and redefining what’s possible in a manufacturing environment. The journey to realizing the full potential of a smart factory is a thrilling exploration of innovation and growth, one that offers immense promise for the future of manufacturing.